Studies and researches left and right has been using 3D printing. The most recent one that was widely publicized in fact was the tiny heart, complete with ventricles and chambers. This time though, researchers have found a way to print even glass.

According to The Optical Society (OSA) Journal Optical Materials Express, a group of researchers headed by Patrick Larochelle (Centre d'Optique, Photonique et Laser at Université Laval in Canada), were able to modify a commercially available 3D printer to print glass. This method of glass printing is based on the commonly used technique of fused deposition modeling, wherein a plastic filament is melted and then extruded layer-by-layer to create detailed 3D objects.

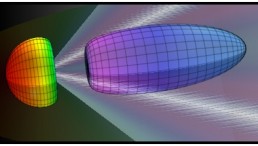

The 3D printing of chalcogenide glass is the first of its kind. Chalcogenide glass is a unique material used to make optical components that operate at mid-infrared wavelengths. The development would pave the way in the manufacture complex glass components and optical fibers for new types of low-cost sensors, telecommunications components and biomedical devices.

"3D printing of optical materials will pave the way for a new era of designing and combining materials to produce the photonic components and fibers of the future," said Yannick Ledemi, a member of the research team. "This new method could potentially result in a breakthrough for efficient manufacturing of infrared optical components at a low cost."

The team modified a commercial 3D printer by increasing its maximum temperature from around 260 °C to 330 °C to enable chalcogenide glass extrusion since chalcogenide glass softens at a relatively low temperature compared to other glasses. Their modifications led to the production of chalcogenide glass filaments with dimensions similar to the commercial plastic filaments normally used with the 3D printer.

"Our approach is very well suited for soft chalcogenide glass, but alternative approaches are also being explored to print other types of glass," said Ledemi. "This could allow fabrication of components made of multiple materials. Glass could also be combined with polymers with specialized electro-conductive or optical properties to produce multi-functional 3D printed devices."Once the design and fabrication techniques are fine-tuned, the researchers say that 3D printing could be used for inexpensive manufacturing of high volumes of infrared glass components or fiber preforms.

"3D printed chalcogenide-based components would be useful for infrared thermal imaging for defense and security applications," continued Ledemi. "They would also enable sensors for pollutant monitoring, biomedicine and other applications where the infrared chemical signature of molecules is used for detection and diagnosis."

The researchers are now working to improve the design of the printer and fine-tuning it to further increase its performance and efficiency and enable additive manufacturing of complex parts or components made of chalcogenide glass.

![Sat-Nav in Space: Best Route Between Two Worlds Calculated Using 'Knot Theory' [Study]](https://1721181113.rsc.cdn77.org/data/thumbs/full/53194/258/146/50/40/sat-nav-in-space-best-route-between-two-worlds-calculated-using-knot-theory-study.png)