Factories with bulk orders are often difficult to manage. Often, activities within the factory or the warehouse are messed-up. But with intelligent and automated techniques like piece picking, things are made easier for pickers.

Using an individual or blended piece picking method, pickers can cut costs to a greater degree without messing big time. Though, the details about this method are given below for you to read in detail.

The Emerging Benefits Of Choosing An Automated Piece Picking Method Are As Followed:

Better productivity.

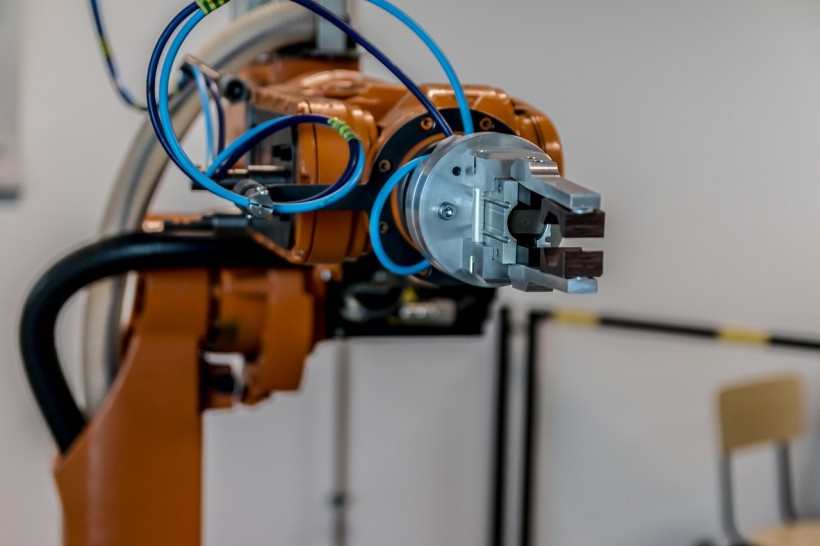

Automated piece picking would mean that items of an order or multiple orders are picked and packed at a greater rate per hour. However, as pickers and the operational heads plan a definite route for robots, productivity eventually enhances.

The most advantageous situation under a piece picking is when:

● The technique is defined,

● Route is clear,

● Pickers know when to redirect the robots,

● Orders are not messed up.

Fewer pickers to hire.

The manufacturing unit or the factory can bear fewer costs by taking piece picking automation in the place. So, there won't be any extensive hiring for manual labor or pickers. In addition, a single robotic machine can perform better and faster picking tasks than a human worker.

It's quite cheap to buy, modify, and configure collaborative mobile machines as per the assembly line routes. Moreover, depending on the accuracy and repeated precision of these robots, walking needs decline. Therefore, the labor is not hired frequently in bulk.

Eventually, such automation leads to lean management and cutting unnecessary costs in fulfilling impending bulk orders.

Better accuracy and efficiency to complete picking orders.

Humans can make dire mistakes and take long enough to pick certain items in an order. It can further delay the processing and completion of an order in the assembly line. Such delays can happen due to fatigue, distraction, and other errors from the human end.

But when you deploy piece picking automated techniques, errors are marginalized and reduced to a certain amount. Then, the manual labor only has to supervise the machine and the carousel.

The automated mobile machines know when to pick the order and when to drop the same. The commands are already in their programs or circuits. Also, with an increase in data points in these mobile machines, the entire routine gets timely updates.

These machines also lead pickers to correct destinations in the warehouses for picking their orders. In addition, these mobile machines often excel in UPC scanning to reduce human error.

Continuous, better, and guaranteed customer satisfaction.

Your customers are happiest when they receive their orders on time without defaults. Efficient and automated piece picking methods to enable faster, more accurate, and impactful order process and completion.

The customers will eventually be happy and satisfied for extended periods when the company chooses the right piece picking technique. However, with limited knowledge, it's impossible to decide the right technique.

But that's alright. No need to sweat over that idea. You can always consult experts in manufacturing and warehousing techniques. They always know the best and efficient piece picking tactics for your factory.

Though, it depends on your inventory management needs, cost, turnaround time, the quality and quantity of each item, and order in the belt.

However, when chosen right, the customers are surely going to get their orders on time. When the system is automated, there are not many things left for you to worry about in this supply chain.

You get open space for your business to boom and operate.

Automated arms to pick and drop need a less complex environment on the floor to work. Therefore, you're not at all in a burden to fill the floor with unnecessary machinery or furniture.

Even the simplest and plain floors can be put to the best use for piece picking activities for your business to scale. So, the entire process of gathering the items of orders to complete the same individually becomes easier, transparent, and not much complicated anymore.

However, your operational heads would have to plan the robotic arm or machine's process and movement in advance. That requires a fair share of experience in the piece picking activities, or you can take expert guidance.

Eventually, you can trust these collaborative mobile robots or machines for upscaling regular operational activities at the factory. First, however, purchase such an arm that has additional features or better guarantee terms.

* This is a contributed article and this content does not necessarily represent the views of sciencetimes.com