Engineering biomaterials that can match the performance of natural cartilage and tendons has long been a goal for scientists but has been difficult. Today, engineers from Cornell University have demonstrated a promising new biohyoid material that mimics natural tissue.

Novel Approach to Fabricating Natural Tissue

A study published in the journal Proceedings of the National Academy of Sciences, titled "Simple synthesis of soft, tough, and cytocompatible biohybrid composites," provides a novel strategy for synthesizing clinical solutions for those struggling with damaged tissue.

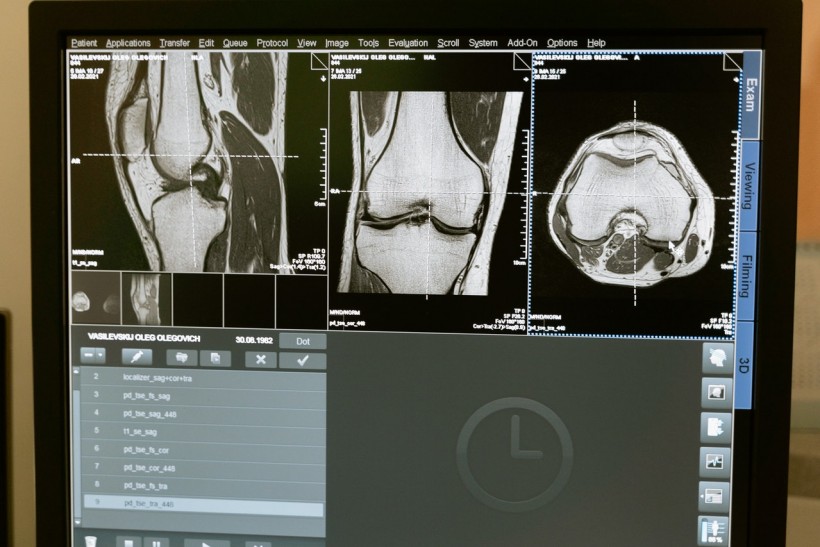

The tissue needs to be soft enough to be bent and flexed yet durable enough to withstand prolonged stress, such as the weight a knee tendon needs to support. When tissue wears out or becomes damaged, collagen hydrogels and other synthetic materials have the potential to serve as replacements. However, neither alone possesses the exact combination of biological and mechanical properties present in natural tissue.

Today, researchers from Cornell University have engineered a novel biohybrid composite material with essential characteristics of natural tissue. The material consists of two ingredients: collagen, giving the material softness and biocompatibility, and a synthetic zwitterionic hydrogel, containing positively and negatively charged molecular groups, reports ScienceDaily.

Lawrence Bonassar and Elaine Sarkaria, co-lead author and Professor in Biomedical Engineering, say that the charge groups interact with the negatively and positively charged groups present in the collagen. The interaction enables the biohybrid material to dissipate energy, achieving high levels of toughness.

ALSO READ: CDC Recorded BA.4 and BA.5 Omicron Sub Variants As Predominant Strains in US

Creating a Biohybrid Tissue

The novel biohybrid composite demonstrated in the study approaches the performance of articular cartilage and other biological tissues. It is shown to possess 40% more elasticity and 11 times the fracture energy of the zwitterionic material by itself.

Co-lead author and assistant professor at Sibley School of Mechanical and Aerospace Engineering, Nikolaos Bouklas, says that the biohybrid material's biocompatibility means it can recruit cells and keep them alive.

He adds that ultimately, the team aims to create something for regenerative medicine, such as pieces of scaffolding that can withstand initial loads until eh tissue fully regenerates. With the hybrid material, it would be easy to 3D print a porous scaffold with cells that will eventually create the actual tissue surrounding the scaffold.

Additionally, the novel material is self-assembling once both ingredients are mixed, creating the same interconnected network of collagen we can see in natural cartilage, which otherwise would be difficult to produce.

The research brought four research labs together from three different departments thanks to a seed grant from Cornell Center for Materials Research. The collage used in developing the biohybrid composite had already been under development in Bonassar's lab. In contrast, the zwitterionic hydrogel was developed by the study's co-authors, Robert Shepperd and Emmanuel Giannelis.

Today, the study's authors continue to research the material and molecular processes behind the synthesis. Bonassar explains that the material is well suited for bioprinting pioneered in his laboratory. Meanwhile, authors have also begun experimenting with 3D printing the hybrid composite, hoping to revolutionize regenerative medicine.

RELATED ARTICLE: 74% of Children Who Undergo Peanut Allergy Treatment Achieved Remission

Check out more news and information on Medicine & Health in Science Times.

![Earth's Quasi-Moon Kamo‘oalewa Could Originate From Lunar Surface Not Asteroid Belt [Study]](https://1721181113.rsc.cdn77.org/data/thumbs/full/53275/89/56/50/40/earths-quasi-moon-kamo-oalewa-could-originate-from-lunar-surface-not-asteroid-belt-study.png)