National Institute of Standards and Technology (NIST) scientists have created a cold atom vacuum system (CAVS). This quantum-based vacuum gauge solves many issues with traditional gauges while producing significantly smaller measurement errors. It passed its first test to be a true primary standard, which is intrinsically accurate without the requirement for calibration. The study was published in AVS Quantum Science.

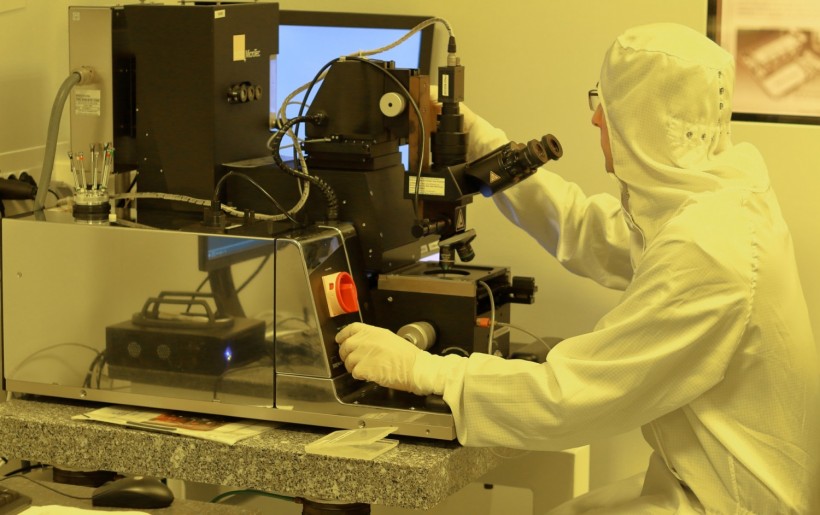

Engineer developing a new process in the cleanroom

Vacuum Gauge System Based on Quantum Physics in a Semiconductor Fabricator

Semiconductor fabricators build their chips layer by layer in vacuum chambers and are interested in precision pressure measurement to ensure a controlled environment to produce a quality product. These vacuum chambers operate at or below one hundred billionths of air pressure at sea level.

Currently, most commercial and research facilities utilize traditional high-vacuum sensors that detect electrical current when an electron source ionizes rarefied gas molecules in a chamber. These ionization gauges must be periodically recalibrated because they might lose their accuracy over time. Additionally, they are incompatible with the recent global initiative to establish the International System of Units (SI) on basic, invariant constants and quantum processes.

The discovery of the NIST system would help the industry as it eliminates the requirement for calibration. Instead of gauging the ionization, the system measures the action of gas molecules (usually hydrogen) on a tiny cluster of trapped lithium atoms that has been cooled to a few thousandths of a degree above absolute zero and illuminated by laser light. The calibration is unnecessary because the interaction dynamics between lithium atoms and hydrogen molecules can be calculated exactly from the first principles.

ALSO READ: Metal nanoclusters can be used as semiconductors: Key properties observed for the first time

Quantum-based Vacuum Gauge System Testing

CAVS, a primary standard and an absolute vacuum sensor, comprise an enclosure attached to the side of and open to a chamber containing the vacuum environment of interest. About a million ultra-cold alkali atoms held in a trap are present in CAVS, and they glow when activated by a laser beam. The gas in the vacuum chamber, primarily hydrogen molecules, that is left after the chamber is pumped down to ultra-high (10-6 Pa) or extreme-high (10-10 Pa) vacuum interacts with the trapped atoms.

In the study, the researchers compared the vacuum values obtained using two portable 7Li cold-atom vacuum standards. In a series of experiments, the researchers found that when they connected two CAVS units to the same chamber, they provided identical measurements with very small errors.

The CAVS devices use the same laser technology and simultaneously measure the vacuum. Together, the two CAVSs discovered a leak with a rate of about 106 Pa l/s. The CAVS recorded a pressure reading of around 40 nPa with a 2.6 percent uncertainty after the leak was repaired. Even when some of the components of the two CAVSs are switched, they still agree within their uncertainties. It was discovered that running the CAVS produced some extra outgassing, on the order of 108 Pa l/s, which can be reduced in the future by improved thermal management.

"The portable cold atom vacuum standard has passed its first big test." If you build two presumably primary standards of any kind, the first step is to ensure they agree with each other when they measure the same thing. If they disagree, they are not standards. " NIST scientist Stephen Eckel said.

The main drawback of this method is that the calibration of the majority of vacuum gauges might change over time. Because of this, it might be challenging to tell the difference between an actual leak and a calibration drift. The CAVS, however, is a primary gauge, so there is no calibration and, consequently, no calibration drift.

The next generation of accelerators and gravity wave detectors may more accurately pinpoint leaks in their massive vacuum systems using three or more CAVS.

The final test of the hypothesis is the construction of a dynamic expansion standard, i.e., a particular vacuum chamber in which a known pressure can be produced and the attachment of a CAVS to measure that pressure. The theory is sound when the pressure is in agreement between the CAVS and the dynamic expansion standard.

RELATED ARTICLE: Scientists Discover The Ability to Determine Semiconductor Nanocrystals with Optical Crystallography Method

Check out more news and information on Technology in Science Times.

!['Cosmic Glitch' in Einstein's Theory of General Relativity Could Be Explained in This New Scientific Tweak [Study]](https://1721181113.rsc.cdn77.org/data/thumbs/full/53435/258/146/50/40/cosmic-glitch-in-einsteins-theory-of-general-relativity-could-be-explained-in-this-new-scientific-tweak-study.jpeg)