Developers are expected to produce high-quality performing yet stable batteries with ever longer lives to suit the expanding worldwide demand for gadgets that can work for extended periods. To consistently improve battery technology, one must ideally be capable of continuously analyzing the changing chemistry inside battery cells under real-world operating settings, identifying possible faults, and optimizing performance.

Collège de France, Réseau sur le Stockage Electrochimique de l'Energie (RS2E), and Université de Rennes (CNRS) have recently developed a system for monitoring the development of electrolyte inside Na- and Li-ion battery cells in real-time and under real-world operating circumstances.

According to Jean Marie Tarascon, a member of the study's authors, batteries constitute electrochemical systems that can conserve electricity in chemical form. Parasitic processes, such as electrolyte deterioration, can help or hurt battery performance. To monitor these complicated chemical processes, pushing the frontiers of operational approaches is critical.

Operando Infrared Fiber Evanescent Wave Spectroscopy

This approach, described in Nature Energy, relies on a measuring process defined by the operando infrared fiber evanescent wave spectroscopy. Tarascon and colleagues previously discovered a mechanism for measuring the pressure and temperature of battery cells under "typical" functioning circumstances. This technique entailed introducing solitary silica optical fibers engraved containing fiber Bragg grating (FBG) sensing devices into the batteries (i.e., permitting periodic modification of the index of refraction of the silica fiber over just a short distance).

Using this method, Tarascon calculated the energy involved with the electrolyte's partial breakdown and the creation of the solid-electrolyte interphase (SEI), the ion-conducting plus electron-insulating layer commonly formed on battery electrodes. Nevertheless, because the measurements are blind to the fiber's chemical surroundings, we could not detect the chemical species participating in the process.

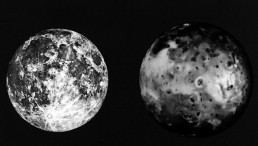

Tarascon and his colleagues' technique for monitoring the development of electrolytes within cells depend on the propagation of infrared light through chalcogenide glass fiber optics put inside a battery. This infrared light reacts with the battery's contents, allowing scientists to recognize and trace the chemical compounds that circulate all around optical fibers.

They observed electrolyte development in addition to the deployment of sodium-lithium ions inside the electrodes based on the state of charge using our approach, said Tarascon. Researchers were also able to prospect the solid electrolyte interphase, the contact between the electrolyte and the negative electrode material, using this technique (SEI). The lifespan of the batteries is determined by this material, which is simultaneously ion-conducting and electron-insulating.

Researchers developed a technique for monitoring the development of electrolytes inside Na- and Li-ion battery cells instantaneously and under real-world operating circumstances.

SEI: Growth and Nucleation

The researchers' technology team helps scientists better understand the chemical processes that occur inside certain battery packs and how they change over time. This same approach can be used to track dissolved substances implicated in the growth and nucleation of the SEI, which is created during the initial phase of a battery's charging, in addition to studying the advancement of electrolytes (i.e., compounds within battery cells that consist ions and can be decayed by electrolysis).

To Tarascon, it now takes quite a while to tune electrolytes and procedures to discover the optimum alternative for an optimal SEI and enhance battery longevity. With their newly developed technique, researchers can watch how each part of the recipe changes, interacts with others, and affects battery performance in real-time, as reported by TechXplore.

Mostly in the future, the new technique developed by this team of experts might aid in the simplification and improvement of battery technology design. However, Tarascon, along with his colleagues, intends to improve current measuring approaches and develop other ones that might be used to collect even more information on SEI layers.

Apart from disclosing chemical species implicated in pathogenic electrolyte degradation, Tarascon's analytical technique sheds light on insertion mechanisms and the Na(Li) inventory inside the cell throughout cycling. Furthermore, the ability to monitor processes like SEI growth and nucleation across cycles would assist in developing better aging simulations and, as a result, more advanced battery administration systems. This operando approach might be used on other energy-storage devices, fuel cells, and supercapacitors.

RELATED ARTICLE: Novel Lithium-Ion Battery Resistant to Extreme Temperatures Allows Electric Cars to Travel Longer on Single Charge

Check out more news and information on Tech & Innovation in Science Times.

![Extinct Giant Salmon Had Tusk-Like Spikes Protruding Out of Its Snout That Can Easily Kill Shark, Other Large Marine Animals [Study]](https://1721181113.rsc.cdn77.org/data/thumbs/full/53304/89/56/50/40/extinct-giant-salmon-had-tusk-like-spikes-protruding-out-of-its-snout-that-can-easily-kill-shark-other-large-marine-animals-study.png)