Scientists from DTU Physics have come up with the world's smallest record that has ever been cut. According to Phys, it only has a diameter of 40 micrometers.

World's Smallest Record

The record featured 25 seconds of the introduction of Rocking Around the Christmas Tree. The single got cut with a machine for nano sculpture known as Nanofrazor, recently gotten from Heidelberg Instruments.

This Nanofrazor machine can engrave 3D patterns to surfaces with resolution in the nanoscale. Interesting Engineering notes that this capacity may lead to the creation of cutting-edge technology across sectors, including magnetic sensors and electron optics.

According to professor Peter Bøggild, he has been conducting lithography for around 30 years, and even if the Nanofrazor has been around for quite a while, its capacity is still similar to that of science fiction. He notes that the most radical endeavor is being able to come up with 3D landscapes that are free-form at remarkably high resolution. Professor Bøggild notes how such gray-scale nanolithography can change the game's name.

ALSO READ: Nano-Petri Dish Created by Scientists Allows the Observation of Atom Behavior in Liquid

Nanofrazor Similar to Computer Numerical Control (CNC) Machine

Instead of a printer that adds material, the Nanofrazor functions similarly to a CNC machine that removes material from exact places. It then leaves the wanted shape behind.

Professor Bøggild notes how they decided to attempt to push through with record printing. They took a snippet of the track and cut it like any other record. However, because of its nanoscale nature, this record cannot be played on a typical record player.

The machine was used as a lathe to cut records. It converts a particular audio signal into a groove spiraled on the medium's surface. In such a case, the medium is another polymer rather than vinyl.

The team even processed the music in stereo. The left channel has lateral wriggles, while the right handles modulation of the depth. To read the record, it is necessary to use an atomic force microscope or the Nanofrazor machine. Nevertheless, this is still possible.

While the Nanofrazor is loaded with capacities, it is not mainly about cutting records and printing images. Professor Bøggild and his teammates have other plans with the machine. For one, they assume that the machine will enable them to come up with 3D nanostructures with extreme precision and to be able to do this at remarkable speeds and less costs. This feat is currently impossible with existing instruments.

The team currently operates with 2D materials. When ultrathin materials get placed on 3D landscapes, they mimic the surface's borders. They become curvy. This is quite a strong and new way to program materials to perform activities that no one would have thought possible.

Ars Technica notes how associate professor Tim Booth also mentions that being able to shape surfaces with precision in a nanolevel is quite a game-changer.

RELATED ARTICLE: Nano-Coated Synthetic Enamel with Properties Near Natural Teeth Coating Developed

Check out more news and information on Nanotechnology in Science Times.

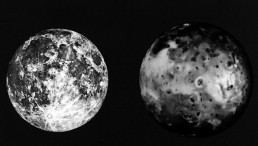

![Earth's Quasi-Moon Kamo‘oalewa Could Originate From Lunar Surface Not Asteroid Belt [Study]](https://1721181113.rsc.cdn77.org/data/thumbs/full/53275/89/56/50/40/earths-quasi-moon-kamo-oalewa-could-originate-from-lunar-surface-not-asteroid-belt-study.png)