A team of researchers from the University of Central Florida and Virginia Tech has published important information regarding the synthesis of ammonia through electrochemical means, which could contribute to food security worldwide.

Ammonia, made up of nitrogen and hydrogen, is a crucial component in many fertilizers used for agriculture. The traditional method for producing ammonia, known as the Haber-Bosch process, is very energy-intensive and requires a significant amount of fuel, consuming 3% to 5% of the world's natural gas supply and contributing more than 1% of global carbon emissions.

By using metal ruthenium as a catalyst, the researchers have found the most effective method to make ammonia using a more environmentally friendly production process - electrochemical synthesis. The researchers stated that this process could be even more sustainable if powered by renewable energy sources like solar or wind.

Nitrogen's Effective Catalyst

Recently, the research findings were published in ACS Energy Letters. Despite numerous studies on electrochemical ammonia production, the researchers indicate that the underlying processes have yet to be fully comprehended. However, this latest study offers a more comprehensive understanding of the reaction process, according to Xiaofeng Feng, a professor in UCF's Department of Physics and co-author of the study. Feng highlights that the results of the extensive research can serve as a valuable guide for the design of more efficient catalysts for sustainable ammonia production.

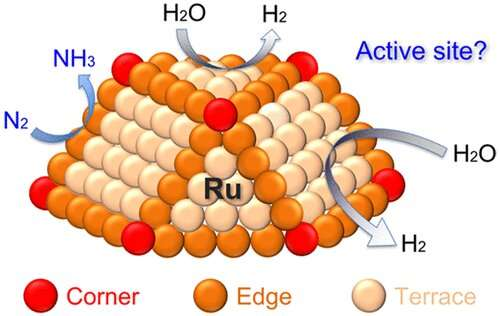

The optimal binding strength of ruthenium with reaction intermediates makes it an extremely effective catalyst for the nitrogen reduction reaction, which results in ammonia production by combining nitrogen and hydrogen from water. By using atomic layer deposition, the researchers maintained precise control of the synthesized nanomaterials at the atomic level, enabling the testing of ruthenium nanoparticles ranging from 2 to 8 nanometers.

Phys reported that during their research, the scientists found that when layering ruthenium atoms into a catalytic structure, a specific arrangement of surface atoms known as the D5 step site was the most active site for the electrochemical nitrogen reduction reaction. The researchers state that the D5 step site stands apart from other sites as it has a "perfect balance," promoting the formation of the N2H intermediate and avoiding poisoning by the NH2 intermediate.

The electrochemical synthesis of ammonia

Ruthenium Nanoparticles Reducing Nitrogen Reaction

After examining the catalytic performance, the researchers discovered that ruthenium nanoparticles of approximately four nanometers showed the best results for the nitrogen reduction reaction. The activity peaked at four nanometers and then declined by five times when the particle size was doubled, emphasizing the significant impact of ruthenium particle size on catalysis.

The previous work of the researchers, aimed at enhancing the efficiency of electrochemical ammonia production, paved the way for the current study by supplying a mechanistic understanding and research methodology. The current study involved collaboration among three research teams. Feng and his students evaluated the ruthenium samples and studied them as catalysts for electrochemical ammonia production. Meanwhile, co-author Parag Banerjee, a UCF's Department of Materials Science & Engineering professor, and his students centered on the accurate synthesis of ruthenium metal nanoparticles in Banerjee's laboratory.

In addition, Virginia Tech professor Hongliang Xin and his student conducted computational studies to simulate and identify the atomic structure that leads to the most efficient catalytic performance. Feng says that the researchers aim to collaborate to create more intricate, effective materials using atomic layer deposition for sustainable ammonia production. They also intend to incorporate the catalyst materials into advanced electrolyzer devices to boost electrically powered ammonia production efficiency and yield rate.

RELATED ARTICLE: Researchers Report Progress on Greener, More Sustainable Hydrogen Extraction from Water

Check out more news and information on Chemistry in Science Times.