Over the past two decades, the potential of thermoelectric materials in emission-free power generation has been recognized, but no devices are available yet to convert the energy they produce.

A team of researchers discovered a new approach to creating thermoelectric modules using silver nanoparticles. Using the nanoparticles in connecting the electrode and metallization layers, they found that silver nanoparticles can be utilized as solder as long as the applied heat is below the melting point of bulk silver.

Power Generation from Thermoelectric Materials

Although heat is an abundant energy source, it is usually wasted, and harvesting a portion of it holds promise for sustainability. Conversion from thermal to electrical energy is traditionally done using solid-state inorganic semiconductors.

A promising technology in the form of thermoelectric materials has gained the interest of experts since it enables efficient energy conversion. Thermoelectric devices can directly convert heat into electricity, which is very useful, especially in remote places with no access to conventional energy sources.

Thermoelectric materials have 5% to 10% conversion efficiency, making them sustainable for energy production. EE Power confirms that thermoelectric materials do not produce any dangerous emissions or pollutants during power operation. This makes them a good option for generating power in places with strict environmental regulations.

READ ALSO: Thermoelectric Materials Made Using Novel Synthesis Strategy

Using Silver Nanoparticle as a Connective Material

Increased interest is shown in thermoelectric materials due to their potential use as a source of clean energy. It works by utilizing heat flow from warmer to cooler areas. As they enable devices that can collect waste heat and convert it to electricity, it promises a breakthrough in improving fuel utilization efficiency.

To do so, the process needs a kind of material with the ability to connect the hot and cool sides of the material electrically and thermally without interfering with its performance. According to the Royal Society Publishing, realizing stable low-resistance electrical contacts between the interconnect electrodes and the thermoelectric materials is the most important factor in developing good quality thermoelectric modules.

A connective material is therefore needed with the right melting point when compared to the device's operating temperature. Such property can be observed in silver, known for having high thermal and electrical conductivity. To address the effect of its high melting point on the stability of thermoelectric materials, a group of researchers from the University of Houston led by M.D. Anderson Professor of Physics Zhifeng Ren took advantage of the lower melting point of silver nanoparticles.

The study's design is based on the idea that a material's thermal conductivity can be reduced by turning them into nanostructures. As the material's grains are smaller, the thermal conductivity of the heat-carrying particles is decreased.

Three state-of-the-art thermoelectric materials operating at different temperatures were used to test the stability of silver nanoparticles. These include a lead tellurium-based module, low-temperature bismuth telluride, and a half-Heusler high-temperature material. Different materials were used to test the ability of the silver nanoparticles to withstand the applied heat.

The result of this study serves as a breakthrough in developing high-performance thermoelectric module design for power generation and other practical applications.

RELATED ARTICLE: Thermoelectric Devices Used to Apply New Approach That Controls Heat Flow, Generates Electricity at Nanoscale

Check out more news and information on Nanoparticles in Science Times.

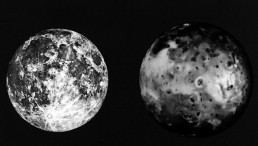

![Earth's Quasi-Moon Kamo‘oalewa Could Originate From Lunar Surface Not Asteroid Belt [Study]](https://1721181113.rsc.cdn77.org/data/thumbs/full/53275/89/56/50/40/earths-quasi-moon-kamo-oalewa-could-originate-from-lunar-surface-not-asteroid-belt-study.png)