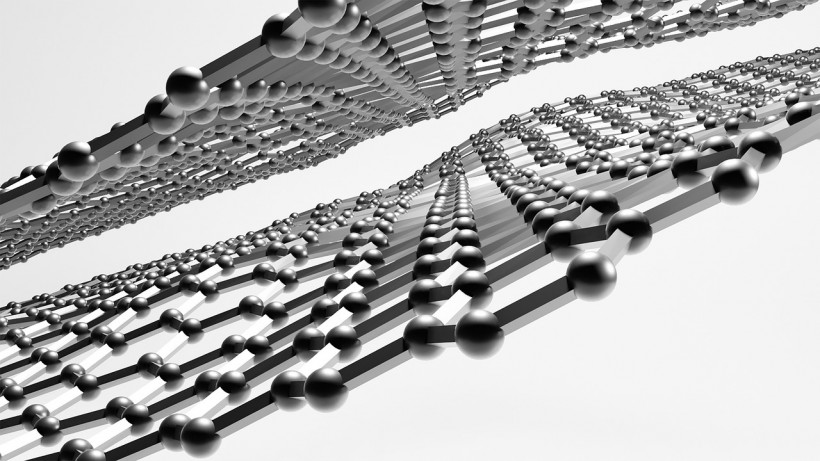

A breakthrough procedure that allows scientists to chemically rip apart and sew together nanoscopic layers of 2D nanomaterials, like a tailor modifying a suit, might be just the instrument for constructing the technology of a sustainable future.

According to Phys.org, researchers discovered MAX phases and MXenes, a method for structurally dividing, editing, and reconstituting layered materials to produce novel materials with highly unique compositions and extraordinary qualities.

New 'Chemical Scissor' Could Cut, Stitch Layered 2D Nanomaterials to Design Future Technology.

New Method to Sharpen the Chemical Scissor to Tailor Layered Nanomaterials

A "chemical scissor" is a substance that reacts with another substance to sever a chemical connection. Over a decade ago, the first set of chemical scissors was revealed, designed to sever carbon-hydrogen bonds in organic compounds.

The international team from Drexel University, China, and Sweden reported on a method to sharpen the scissors so that they can cut through extremely strong and stable layered nanomaterials in a way that breaks atomic bonds within a single atomic plane.

As per the paper titled "Chemical Scissor-Mediated Structural Editing of Layered Transition Metal Carbides," published in Science, the team fundamentally changed the material's composition in a single chemical "snip."

Yury Gogotsi, Ph.D., Distinguished University Professor and Bach chair in Drexel's Faculty of Engineering and one of the study's authors, said this discovery ushers in a new age of materials science, allowing for atomistic engineering of two-dimensional and layered materials.

The study demonstrated how to construct and disassemble these materials like LEGO pieces, leading to the invention of intriguing new materials that were not even anticipated to exist until now."

Gogotsi and other researchers at Drexel have been studying the Mxenes nanomaterials discovered in 2011, which started as a precursor material for the MAX phase. MAX is a chemical portmanteau with three layers: M, A, and X. When added with a strong acid; it could etch away the A layer and create the MXene, a more porously layered material.

The finding followed widespread enthusiasm over graphene, a 2D nanomaterial thought to be the strongest material in existence, when the team of academics who discovered it earned the Nobel Prize in 2010. The discovery of graphene widened the hunt for additional atomically thin materials with exceptional characteristics, such as MXenes.

Just Like Performing a Surgery

On the other hand, Gogotsi and Qing Huang from the Chinese Academy of Sciences explained in their paper that using the chemical scissor to edit the layered transition metal carbides structurally is like performing surgery.

First, they used a Lewis acidic molten salt (LAMS) etching protocol to remove the A layer of the MAX phase and replace it with chlorine. The chemical can be sliced apart using another set of chemical scissors composed of zinc. It becomes the raw materials of MAX phases that the addition of mortar through intercalation results in a new MAX phase that can be used to create new MXenes.

Gogotsi said this method is like making a surgical cut of the MAX structure and peeling it in layers before reconstructing it with new and different material. It also produced new and unusual chemistries that can make novel and unique MAX phases and use them to produce MXenes tailored to optimize various properties.

Moreover, the team used it to create MXenes that could host new guest atoms that it previously would not have been able to accommodate, expanding MXene materials.

The next step for this research is the delamination of 2D and 3D layered carbides and metal-intercalated 2D carbides into single, few-layered nanosheets that can be optimized to store energy for electronics and other applications.

RELATED ARTICLE: "Game-Changing" Nanomaterials Are Both Generators and Sensors; Here's How They Work

Check out more news and information on Nanotechnology in Science Times.