Efficient leak detection for pharmaceutical containers keeps medications safe and effective from the moment they leave production until they reach patients. Every sealed vial, blister pack, or container needs to stay completely sterile throughout its journey. Even a tiny breach that you can't see with your eyes can ruin an entire batch, causing contamination and putting patients at risk.

Here's what makes this critical. Old testing methods would often break or damage the products during inspection. That creates waste and limits how thoroughly you can check quality. Today's pharmaceutical manufacturers need systems that verify container closure integrity testing (CCIT) without destroying what they're testing. This move toward non-destructive methods has changed how the entire industry handles quality control.

Understanding Modern Pharmaceutical Leak Detection Technology

The science behind pharmaceutical leak detection has come a long way from basic visual checks or opening random samples. Advanced vacuum testing systems now catch leaks as tiny as a few microns. These are breaches you'd never spot with old-school methods.

ACRN's vacuum leak testers work on simple principles but give you powerful results. The system puts pharmaceutical containers inside a sealed chamber where controlled vacuum conditions show even the smallest problems. Products with liquids will leak outward when you apply a vacuum. Air-filled packages reveal their weak spots through bubble formation when you test them under water.

Three Main Testing Methods for Different Products

Different pharmaceutical products need different testing approaches. Each method targets specific packaging types and gets results in its own way.

Dry testing handles liquid or semi-viscous products like injectable vials and even perfume bottles. The vacuum creates pressure differences that make leaking products reveal themselves right away. You'll see the problem immediately without waiting.

Immersion testing works for packaging that contains air. Think food trays and certain pharmaceutical containers. When you put them underwater and apply a vacuum, any sealing defect releases visible bubbles. You can pinpoint exactly where the breach is located.

Methylene blue testing serves tablet blisters and other compact air-filled products. This method uses atmospheric pressure to return to pull colored dye through any microscopic openings. The blue stain shows you precisely where the package failed.

Why Container Closure Integrity Testing Matters More Than Ever

Regulatory bodies around the world have gotten stricter about pharmaceutical packaging integrity. The FDA and European Medicines Agency now require solid CCIT protocols that prove your container systems maintain sterility for their entire shelf life. You need to show that your packaging blocks contamination, keeps moisture out, and prevents oxygen from getting in.

These rules exist for good reasons. Contaminated pharmaceuticals have caused serious health problems before. Injectable medications need absolute sterility because they skip past the body's natural defenses. Oral medications need protection from moisture and oxygen that break down active ingredients. Biological products face even tougher standards because they're so sensitive, and contamination can be devastating.

Advanced Features That Set Modern Systems Apart

The pharmaceutical packaging integrity testing equipment available today does far more than basic pass or fail checks. Modern systems give you control, documentation, and flexibility that older machines simply couldn't provide.

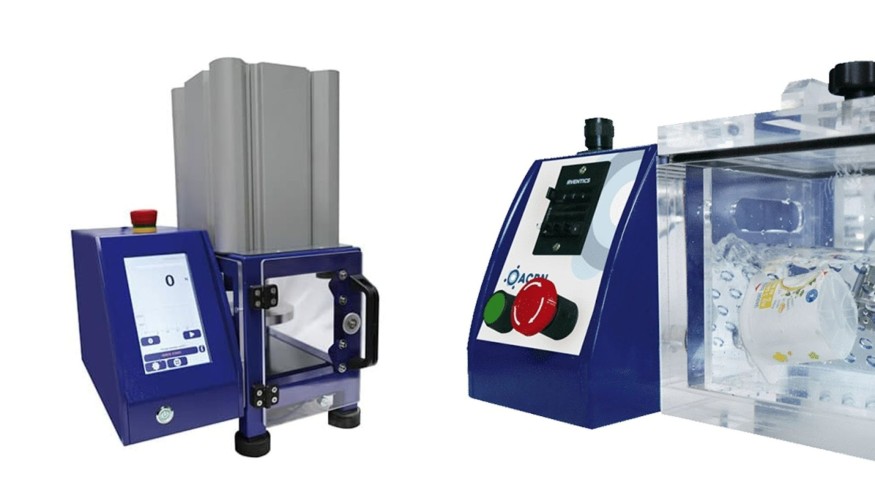

ACRN's AgiLeak system shows what next-generation pharmaceutical leak detection looks like. The touch-sensitive control panel makes operation straightforward and cuts down training time. You'll have fewer operator errors, too. Unlike purely mechanical systems, this electropneumatic design offers unlimited test duration and precise digital pressure monitoring down to negative 950 mbar vacuum levels.

Versatility Beyond Standard Leak Testing

The system doesn't just find leaks. It performs resistance testing and explosion tests for packages that might fail under pressure. You can create custom test programs for unique packaging formats or special product requirements. The AgiLeak stores these programs so you get consistent testing no matter who's running the machine or what shift they're on.

Data Management for Modern Compliance

The system exports test results so you can document everything and spot trends over time. Profile management lets you set different user access levels. This protects sensitive test parameters while giving operators the information they need to do their jobs. CFR 21 Part 11 compliance means your electronic records meet FDA requirements for pharmaceutical manufacturing.

Comparing Pneumatic and Electropneumatic Solutions

Production environments vary widely, so equipment needs differ too. ACRN makes three distinct vacuum leak tester models to match different operational needs and budgets.

CTS: Pure Simplicity

The CTS is fully pneumatic and needs zero electrical maintenance. It runs entirely on compressed air. The three-way valve design makes operation easy even for brand-new staff. You get immediate visual confirmation through the transparent vacuum bell and analog manometer. For facilities with basic testing needs and tight budgets, the CTS delivers reliable results without extra bells and whistles.

CTE: Adding Timing Control

The CTE builds on the pneumatic foundation by adding test duration management up to 999 seconds. It still runs solely on compressed air like the CTS. This timing capability keeps test protocols consistent across batches and operators. The emergency stop button gives operators instant control if they spot potential issues during testing. The CTE suits manufacturers who need reproducible test timing but want to skip electronic maintenance headaches.

AgiLeak: Full Digital Control

The AgiLeak brings complete digital control and data management to pharmaceutical leak detection. You can use a vacuum pump option and skip compressed air infrastructure entirely, though it works with either system. The digital pressure gauge provides exact readings that analog systems can't match. Unlimited test time works for special protocols with challenging packaging formats. The data export and program recording features support modern quality management systems and make regulatory compliance documentation much easier.

Practical Implementation Across Pharmaceutical Applications

Real pharmaceutical manufacturing throws all kinds of packaging challenges at you. Injectable vials need different testing than blister packs. Prefilled syringes require protocols that differ from IV bags. Your leak detection system needs to adapt to this variety while keeping accuracy consistent.

Flexible Configurations for Different Product Sizes

Sealing box setups offer flexibility for various product sizes. Cover-access boxes come in 14 standard sizes with custom options when you need them. Top-loading design works great for automated production lines where overhead access makes sense. Door-access boxes provide front-loading convenience for manual operations or tight spaces. Three standard sizes handle most needs, with custom dimensions available for unusual products.

Protecting Finished Packaging

Anti-marking kits keep finished packaging looking pristine during testing. Pharmaceutical products often feature labels, printing, or decorative elements that need to stay perfect. The specialized contact surfaces prevent scratches and marks while maintaining the seal needed for accurate vacuum testing. This matters especially for products heading to retail channels where appearance affects whether consumers trust the product.

Ensuring Long-Term Reliability and Compliance

Quality testing equipment needs regular attention to stay accurate. You can't just buy a system and forget about it for years.

Calibration Services That Come to You

Equipment calibration maintains measurement accuracy as time passes. ACRN's metrology laboratory has handled calibration services since 2012. They cover force, torque, and pressure measurements that keep leak detection accurate. The laboratory maintains standards linked to COFRAC, which traces back to national measurement systems.

On-site calibration services cut down production downtime. ACRN technicians bring calibrated standards right to your manufacturing facility. They perform verification and adjustment without taking your equipment away. Regional tours group nearby facilities into efficient service routes to optimize costs. For ACRN equipment, these visits include preventive maintenance that extends system life and stops unexpected breakdowns.

Documentation and Validation Support

The thermal printer option gives you immediate hard-copy documentation of test results. Each ticket records test parameters, results, and timestamps that support batch release decisions. This physical record backs up electronic data storage and provides redundancy for critical quality documentation.

Qualification services help pharmaceutical manufacturers meet validation requirements. ACRN provides documentation packages that support Installation Qualification, Operational Qualification, and Performance Qualification protocols. These services take pressure off internal validation teams while making sure equipment meets specified performance criteria.

Choosing the Right Leak Detection System for Your Facility

Picking the right pharmaceutical packaging integrity testing equipment takes careful thought about production volumes, packaging types, and regulatory requirements. High-volume automated lines benefit from systems with fast cycle times and automated data recording. Small-batch specialty manufacturers might value flexibility and custom test protocols over pure speed.

Budget goes beyond the sticker price. Total cost of ownership includes calibration, maintenance, operator training, and system upgrades down the road. Purely pneumatic systems keep maintenance minimal but lack the data management features that electronic systems provide. The right choice balances what you need today with where you're headed as production scales or regulations change.

ACRN's French engineering and manufacturing means responsive support and custom development when you need it. The company builds equipment meant to last over 20 years. This sustainability approach cuts long-term costs and reduces environmental impact. Local European manufacturing keeps supply chains short and support close by.

Modern pharmaceutical leak detection protects patients, keeps you compliant with regulations, and reduces waste from false rejects. The technology has reached a point where non-destructive testing delivers both precision and practicality. Manufacturers who invest in advanced CCIT systems set themselves up to meet current standards while preparing for whatever regulatory changes come next.

© 2026 ScienceTimes.com All rights reserved. Do not reproduce without permission. The window to the world of Science Times.